Category: Construction Costs

Meme Weeding: High Wages and Baumol’s Cost Disease

The Baumol effect is a mechanism for how the real costs of goods and services can rise over time: wages rise due to economy-wide productivity growth, including in sectors with no productivity growth, and this raises their overall real costs of production. The original example for Baumol was classical concerts – they use the same number of musicians as in the 19th century, but wages have increased from 19th-century levels. More generally, it’s also used to explain higher real costs of services as service productivity growth lags manufacturing productivity growth.

Unfortunately, I’ve also seen people use Baumol as a way of explaining rising infrastructure construction costs, for which it is not at all a good explanation. In fact, even though growth in average infrastructure costs over time is documented, there is very little cross-national correlation between GDP per capita and per-km subway construction costs. Notably, the Anglosphere’s very high construction costs affect not just very rich countries like the US and Singapore but also ones that are poorer than the Western European average, like New Zealand, Ireland (which has high GDP per capita due to corporate profits but unimpressive local wages), or increasingly the United Kingdom. Conversely, Nordic and Swiss wealth has not at all led to high construction costs, and until recently the Nordic countries and Switzerland had some of the world’s lowest tunneling costs.

Metro construction costs and GDP per capita

In an earlier version of the construction cost database, there was some positive correlation between GDP per capita and construction cost per km (about 0.23), but nearly all of it came from the fact that poorer countries tend to build more els and fewer subways; correcting for that, the correlation fell to about 0.04, and turned negative if New York and Singapore were dropped. We made a scattergram at the national level:

While looking at the scattergram, bear in mind that the poorest country as of 2020 on our list, Pakistan (the small gray circle touching the much larger gray circle of India), built an all-elevated line, and in general, substantially-elevated or even all-elevated lines are common in developing Asia, including Vietnam, Bangladesh, Indonesia, the Philippines, Thailand, and India. The only all-underground Indian line in our database, Mumbai Metro Line 3, cost $535 million/km in 2023 PPP dollars; Mumbai Line 11 and Chennai’s first-phase program are the only other two items that are majority-underground, both a bit more than $300 million/km.

At this point, even if we restrict our attention to Europe, the correlation between GDP per capita and construction costs per km isn’t clear. For example, Railway Gazette has just reported on the groundbreaking of the first metro line of Cluj-Napoca, to cost 13.7 billion lei/21 km, which is $8 billion in PPP terms, or $380 million/km. But then rounding up the bottom of the EU’s GDP per capita table is Bulgaria, with fairly low costs.

This is not supposed to happen if the Baumol effect is what’s going on. Grocery prices in developing countries are lower than at first-world discounters like Walmart or Aldi, even in PPP terms. Even at tourist traps, the prices are usually lower than where the tourists came from, not because retail and food service are atypically efficient in developing countries, but because these are labor-intensive industries and labor wages are lower in Thailand or China, let alone in India or Pakistan, than in the US or Germany.

The issue of the Anglosphere

The Anglosphere has atypically high construction costs. A dummy variable that takes the value 1 in the US, Canada, Australia, New Zealand, the United Kingdom, Singapore, Hong Kong, and (when it starts building) Ireland, and 0 elsewhere, has a correlation of 0.41 with per-km construction costs. In contrast, the tunnel percentage only has 0.15 correlation, due to the aforementioned effect of high-cost developing countries building els. I’ve heard the high Anglosphere costs blamed on a kind of areal Baumol effect: high pay in professional services drags the costs up, on the theory that the United Kingdom may be poorer than Germany and no richer than France, but at least it has productive London finance that drags engineering wages up, so Britain can’t just Germanize or Francize, right?

Well, no. British engineering wages are not at all high by Continental Western European standards. London finance pays a lot, but also has been stagnating for a while, and a number of professional service firms and regional HQs have left the country in response to Brexit to locate in the rump-EU, for which Amsterdam is a popular destination. British costs remain high, and if anything, they’re exploding again. The Bakerloo line extension is now projected to cost £5-8 billion in 2023 prices for what looks like 8 km, which is around $1.2 billion/km in PPP terms, somewhat more than the much more complex Crossrail and about twice as expensive as the comparably complex Northern line extension to Battersea.

Then-Singaporean minister of transport Khaw Boon Wan excused the meteoric growth in Singapore’s MRT construction costs on the grounds that the Singaporean economy had grown rapidly as well. But we’re seeing the same cost explosion in the slower-growing United Kingdom, and conversely we’re not seeing high costs in fast-growing South Korea. New Zealand, which has had okay growth but from low levels for a Western country and remains poorer than Italy, has these extreme costs as well. It’s not that the Anglosphere is rich; it’s that it’s the Anglosphere and builds inefficiently.

So why have costs grown?

While there is no correlation between subway tunneling costs and GDP per capita, there is an evident secular growth in costs over time. It’s not uniform everywhere – German costs are barely up compared with the 1970s and Italian costs are slightly down – but it’s huge in the Anglosphere and also evident elsewhere (for examples, in France and in the Nordic countries). So what’s going on?

Well, we’ve divided the New York cost premium into three tranches: labor (mostly overstaffing, not high wages), station and system design, and procurement and soft costs. All three show evidence of having gotten worse, the first in the Northeastern United States and the other two throughout the Anglosphere and sometimes also elsewhere.

Ad labor, staffing levels in New York are just higher than elsewhere. More workers are required to service a tunnel-boring machine in New York than in Istanbul, let alone richer European cities. This is, in theory, an eexample of the Baumol effect: higher wages raise the real cost in an industry without productivity growth. But in fact, there has been plenty of productivity growth in this industry, the Northeast just refuses to make use of it. Stockholm has been able to keep up and keep its labor share of the hard costs to the same 20-something% as Turkey and Italy; New York and other Northeastern US cities are in the 40-60% range instead. Swedish construction productivity has grown at slower rates than the overall Swedish economy, but American construction productivity has fallen.

Ad station and system design, we have pointed out that stations for Second Avenue Subway Phase 1 dug a cavern twice as long as necessary for the train, for the benefit of extensive back-of-the-house spaces, where in non-UK Europe and in China, the digs are typically a single-digit percent longer than the train. This is a general North American problem, also evident in Los Angeles and Vancouver, and I believe also in London. It’s also a new problem: in the 1980s, the overage in the United States was small, comparable to contemporary European levels. Then there’s the issue of poor standardization of materials, systems, and designs; we are uncertain whether this is a growing or longstanding problem, but it is smaller in magnitude than that of excessive station size, and in general, standardization is more important in a richer economy than a poorer one since the richer economy will have more reliance on big businesses with division of labor, which is also one of the speculated causes of the falling construction productivity (it’s a less standardized sector).

Finally, ad procurement, the invention of the globalized system in which state planning is outsourced to private consultancies, and with time even the supervision of the consultants is outsourced to consultants, is an Anglosphere special, dating from the 1990s onward. This system comprises design-build procurement (confusingly called progressive design-build in New York), very large contracts sometimes growing to $1 billion apiece, lump-sum rather than itemized contracts, and privatization of risk. It’s turned entire countries, like the United Kingdom, incapable of building more than about one line per generation. The Nordic countries have been affected as well, leading to sharp cost growth from very low levels to rather average ones. Canada went from fairly normal costs in the early 2000s to building the most expensive subway outside New York with the new Ontario Line cost overruns, and this can be traced to Toronto officials visiting Madrid, a city that sticks to traditional design-bid-build procurement, and coming back convinced that to imitate Madrid’s low costs Toronto should adopt design-build.

None of this is the Baumol effect or some general cost disease. When agency officials lose interest in building things and instead want to outsource their own jobs to consultants, it’s not Baumol; it’s experimenting with a new way of project delivery and then refusing to admit that it’s a failure. The same is true when nobody bothers to say no as each operating department demands more back-of-the-house space until half the station dig is about providing high-cost underground break rooms and storage rather than about providing space for trains and passenger circulation.

It’s a comforting story for Americans, Brits, and Singaporeans to tell themselves that their infrastructure costs are so high as a byproduct of their wealth. It happens to be entirely false. It’s not even interestingly wrong; it’s just plain wrong, ignorant of the explosion in station size, of the failures of the globalized system of project delivery, and (in New York) of labor productivity innovations elsewhere. The Anglosphere is not expensive because it’s ahead in anything, but rather because it’s behind. And as we see in the United Kingdom, it doesn’t even require American or Singaporean wealth to be totally incurious of Continental European success.

Standardizing the Right Way

Picking consistent standards in order to make use of economies of scale is an important part of good planning. In our construction costs report, we attribute a high cost premium on systems and finishes in New York to lack of standardization of station designs and parts, to the point that the three stations of Second Avenue Subway used two different escalator vendors. This point has appealed to a number of area activists, who reach to not just what we report cross-nationally but also American history. John Pegram, who comments here as BQRail and writes an excellent blog on Substack, gave the example of the PCC streetcars of interwar America a week ago, and I promised I’d follow up on this; the news of the cancellation of congestion pricing delayed this post somehow but it’s still important to discuss. The issue here is that good public transportation procurement requires not just consistent standards, but also good ones, which give international vendors a familiar environment and keep in touch with technological advances.

The starting point for me is that the rolling stock on American subways and commuter rail is fairly standardized. New York City Transit procured standard designs in the 1990s, dubbed the R110A and R110B, and for decades kept buying trains based on these designs. In the 1990s and 2000s, it worked, in the sense that the trains were of comparable quality and cost to rolling stock in other large cities (although they were on the heavy side). But over time, technology diverged, and by the 2010s, a cost premium started to appear. By now, NYCT subway car contracts have a noticeable premium over the European norm, even if this premium is far smaller than the infrastructure cost premium.

Commuter and intercity rail cars have a similar issue with what the standard is. American commuter rail cars follow a few standard designs – the EMU design (in either the LIRR/Metro-North version or the SEPTA one), and the unpowered car hauled by a diesel locomotive one. DMU designs are not at all standard, and do have cost premiums as a result, especially since these are also small orders. That said, nearly all American commuter rail ridership is on EMUs or locomotive-hauled trains (usually diesel, occasionally electric), and those, too, have their problems.

The most glaring problem is that those designs are not at all what the rest of the world does. A few of the changes are modular, including the platform height and the loading gauge. The others are not; the consultants who write the design specs do so without trying to fit themselves to common products made by the multinational vendors.

Then, those specs are extremely detailed; there’s little room for a vendor to try to pawn off a standard Coradia or FLIRT and make that fit with little modification. The RFPs run into the deep hundreds of pages; SEPTA had one with more than 500 pages, and Amtrak’s most recent one ran to, I believe, 1,000. They define even what a train is, as opposed to the looser RFPs common in Europe – Spanish RFPs are 50-70 pages and have single-digit summaries, detailing just how many cars are needed, what the loading gauge is, what electrification is required, and what the expected performance level is.

Designs exist that do dialog with the international vendors and aim at a comparable product – the FRA reform process that led to alt-compliance did exactly that. But then no American commuter rail operator has bothered to make use of alt-compliance; they still buy the heavy, low-performance, low-reliability equipment that they’re used to buying, even as technology marches on and vendors don’t specialize in making that anymore.

The original example of the PCC standard is well-taken in the sense that there need to be repeatable standards. However, it’s important to understand that technological advances in trains exist in East Asia and Europe, and not in North America. American standardization needs to be around what is sold on the other side of either the Atlantic or the Pacific, with no wheel reinvention, and no “we are familiar with this so we’ll keep buying this” excusemaking.

American Myths of European Poverty

I occasionally have exchanges on social media or even in comments here that remind me that too many people in the American middle class believe that Europe is much poorer than the US. The GDP gap between the US and Northern Europe is small and almost entirely reducible to hours worked, but the higher inequality in the US means that the top 10-20% of the US compare themselves with their peers here and conclude that Europe is poor. Usually, it’s just social media shitposting, for example about how store managers in the US earn the same as doctors in Europe. But it becomes relevant to public transit infrastructure construction in two ways. First, Americans in positions of authority are convinced that American wages are far higher than European ones and that’s why American construction costs are higher than European ones. And second, more broadly, the fact that people in positions of authority really do earn much more in the US than here inhibits learning.

The income gap

The United States is, by a slight amount, richer than Northern Europe, which for the purposes of this post comprises the German-speaking world, the Nordic countries, and Benelux. Among the three largest countries in this area, Germany is 16.5% poorer than the US, the Netherlands 8.3% poorer, Sweden 14.3%. This is more than anything an artifact of shorter working hours – Sweden has an ever so slightly larger GDP per hour worked, the other two are 6-7% poorer per hour worked. All three countries have a much higher 15-64 labor force participation rate than the US, but they’re also older, which in the case of Germany actually gets its 15+ rate to be a hair less than the US’s. But there’s much more part-time work here, especially among women, who face large motherhood penalties in German society (see figures 5-7 in Herzberg-Druker, and Kleven et al). Germany is currently in full employment, so it’s not about hidden part-time work; it’s a combination of German-specific sexism and Europe-wide norms in which workers get around six weeks of paid vacation per year.

One implication of the small gap in income per hour is that wages for the same job are likely to be similar, if the jobs pay close to the mean wage. This is the case for tunnel miners, who are called sandhogs in the United States: the project labor agreements in New York are open – the only case in which itemized costs are publicly available – and showcase fully-laden employment costs that, as we document in our construction costs reports, work out to around $185,000/year in 2010 prices; there is a lot of overstaffing in New York and it’s disproportionately in the lower-earning positions, and stripping those, it’s $202,000/year. I was told that miners in Stockholm earn 70,000 kronor/month, or about $100,000/year in PPP terms (as of 2020-1), and the fully-laden cost is about twice that; a union report from the 2000s reports lower wages, but only to about the same extent one would expect from Sweden’s overall rate of economic growth between then and 2021. The difference at this point is second-order, lower than my uncertainty coming from the “about” element out of Sweden.

While we’re at it, it’s also the case for teachers: the OECD’s Education at a Glance report‘s indicator D3 covers teacher salaries by OECD country, and most Northern European countries pay teachers better than the US in PPP terms, much better in the case of Germany. Teacher wage scales are available in New York and Germany; the PPP rate is at this point around 1€ = $1.45, which puts starting teachers in New York with a master’s about on a par with their counterparts in the lowest-paying German state (Rhineland-Pfalz). New York is a wealthy city, with per capita income somewhat higher than in the richest German state (Bavaria), but it’s not really seen in teacher pay. I don’t know the comparative benefit rates, but whenever we interview people about European wage rates for construction, we’re repeatedly told that benefits roughly double the overall cost of employment, which is also what we see in the American public sector.

The issue of inequality

American inequality is far higher than European inequality. So high is the gap that, on LIS numbers, nearly all Western European countries today have lower disposable income inequality than the lowest recorded level for the US, 0.31 in 1980. Germany’s latest number is 0.302 as of 2021, and Dutch and Nordic levels are lower, as low as 0.26-0.27; the US is at 0.391 as of 2022. If distributions are log-normal (they only kind of are), then from a normal distribution log table lookup, this looks like the mean-to-median income ratios should be, respectively, 1.16 for Germany and 1.297 for the US.

However, top management is not at the median, and that’s the problem for comparisons like this. The average teacher or miner makes a comparable amount of money in the US and Northern Europe. The average private consultant deciding on how many teachers or miners to hire makes more money in the US. A 90th-percentile earner is somewhat wealthier in the US than here, again on LIS number; the average top-1%er is, in relative terms, 50% richer in the US than in Germany (and in absolute terms 80% richer) and nearly three times as rich in the US as in Sweden or the Netherlands, on Our World in Numbers data.

On top of that, I strongly suspect that not all 90th percentile earners are created equal, and in particular, the sort of industries that employ the mass (upper) middle class in each country are atypically productive there and therefore pay better than their counterparts abroad. So the average 90th-percentile American is noticeably but not abnormally better off than the average 90th-percentile German or Swede, but is much better off than the average German or Swede who works in the same industries as the average 90th-percentile American. Here we barely have a tech industry by American standards, for example; we have comparable biotech to the US, but that’s not usually where the Americans who noisily assert that Europe is poor work in.

Looking for things to mock

While the US is not really richer than Northern Europe, the US’s rich are much richer than Northern Europe’s. But then the statistics don’t bear out a massive difference in averages – the GDP gap is small, the GDP gap per hour worked is especially small and sometimes goes the other way, the indicators of social development rarely favor the US, immigration into Western Europe has been comparable to immigration to the US for some time now (here’s net migration, and note that this measure undercounts the 2022 Ukrainians in Germany and overcounts them in Poland).

So middle-class Americans respond by looking for creative measures that show the level of US-Europe income gap that they as 90th-percentile earners in specific industries experience (or more), often dropping the PPP adjustment, or looking at extremely specific things that are common in the US but not here. I’ve routinely seen American pundits who should know better complain that European washing machines and driers are slow; I’m writing this post during a 4.5-hour wash-and-dry cycle. Because they fixate on proving the superiority of the United States to the only part of the world that’s rich enough not to look up to it, they never look at other measures that might show the opposite; this apartment is right next to an elevated train, but between the lower noise levels of the S-Bahn, good insulation, and thick tilt-and-turn windows, I need to concentrate to even hear the train, and am never disturbed by it, whereas American homes have poor sound insulation to the point that street noise disturbs the sleep.

Learning to build infrastructure

The topline conclusion of any American infrastructure reform should be “the United States should look more like Continental Europe, Turkey, non-Anglophone East Asia, and the better-off parts of Latin America.”

If it’s written in the language of specific engineering standards, this is at times acceptable, if the standards are justified wholly internally (“we can in fact do this, here’s a drawing”). Even then, people who associate Americanness with their own career success keep thinking safety, accessibility, and similar issues are worse here, and ask “what about fire code?” and then are floored to learn that fire safety here is actually better, as Stephen Smith of Market Urbanism and the Center for Building constantly points out.

But then anything that’s about management is resisted. It’s difficult to convince an American who’s earning more than $100,000 a year in their 20s and thinks it’s not even that much money because their boss is richer that infrastructure project management is better in countries where the CEO earns as much money as they do as an American junket assistant. Such people readily learn from rich, high-inequality places that like splurging, which are not generally the most productive ones when it comes to infrastructure. Even Americans who think a lot about state capacity struggle with the idea that Singapore has almost as high construction costs as the US; in Singapore, the CEO earns an American salary, so the country must be efficient, right? Well, the MRT is approaching $1 billion/km in construction costs for the Cross-Island Line, and Germany builds 3 km of subway (or decides not to build them) on the same budget and Spain builds 6 km, but Europe is supposedly poor and Americans can’t learn from that.

The upshot is that even as we’re seeing some movement on better engineering and design standards in the United States, resulting in significant cost savings, there’s no movement for better overall management. Consultant-driven projects remain the norm, and even proposals for improving state capacity are too driven by domestic analysis without any attempt at international learning or comparativism. Nor is there any effort at better labor efficiency – management in the US hates labor, but also thinks it’s entirely about overpaid workers or union safety rules, and doesn’t stoop to learn how to build more productively.

Quick Note: What the Hell is Going on in San Jose?

The BART to San Jose extension always had problems, but somehow things are getting worse. A month and a half ago, it was revealed that the projected cost of the 9.6-kilometer line had risen to $12.2 billion. Every problem that we seemed to identify in our reports about construction costs in New York and Boston appears here as far as I can tell, with the exception of labor, which at least a few years ago showed overstaffing in the Northeastern United States but not elsewhere. In particular, the station and tunnel design maximizes costs – the first link cites Adam Buchbinder on the excessive size of the digs. Unfortunately, the response by the Valley Transportation Authority (VTA) to a question just now about the station shows that not only are the stations insanely expensive, but also not even convenient for passengers (Twitter link, Nitter link).

Cost breakdown

The March 2024 agenda (link, PDF-pp. 488-489) breaks down the costs. The hard costs total $7 billion; the systems : civils ratio is 1:3.5, which is not bad. But the overall hard costs are still extreme. Then on top of them there are soft costs totaling $2.78 billion, or 40% on top of the hard costs. The same percentage for Second Avenue Subway was 21%, and the norm for third-party consultants for the Continental European projects for which we have data (in Italy, Spain, Turkey, and France) is to charge 5-10%. Soft costs should not be this high; if they are, something is deeply wrong with how the agency uses consultants.

Large-diameter tunnel boring machines

The BART to San Jose project has long had two distinct options for tunnels and station: twin bores, and single bore. The twin bore option is conventional construction of two bored tunnels, one for each track, and then stations to be built as dedicated civil construction projects outside the tunnel; this is how most subways are built today. The single bore option is a large-diameter tunnel boring machine (TBM), with the bore large enough to have not just two tracks side by side, but also platforms within the bore, eliminating the need for mined station caverns or for extensive cut-and-cover station digs. Both options cleared environmental reviews; VTA selected the single bore option, which has been controversial.

I’ve written positively about large-diameter TBMs before, and I don’t think I’ve written a full post walking this back. I’ve written about how large-diameter TBMs are inappropriate for San Jose, but the truth is that the method is not treated as a success elsewhere in urban rail, either. This is controversial, and serious engineers still think it works and point to successes in intercity rail, but in urban rail, the problems with building settlement are too serious. The main example of a large-diameter TBM is Barcelona L9/10, which uses the method to avoid having to open up streets under multiple older metro tunnels in Barcelona; it also has high construction costs by Spanish standards (and low costs by non-Spanish ones). In Italy, whose construction costs are also fairly low if not as low as in Madrid, engineers considered using large-diameter TBMs for the sensitive parts of Rome Metro Line C but then rejected that solution as too risky, going for conventional high-cost mined stations instead.

Regardless of the wisdom of doing this in Southern Europe, in San Jose it is stupid. There are wide streets to dig up for cut-and-cover stations. Then, the implementation is bad – the station entryways are too big, whereas Barcelona’s are small elevator banks, and the tunnel bore is wide enough for a platform and two tracks on the same level whereas Barcelona has a narrower bore with stacked platforms.

Thankfully, it is administratively possible to cancel the single bore option, since the twin bore option cleared the environmental reviews as well, and in 2007 was already complete to 65% design (link, PDF-p. 7). Unfortunately, there isn’t much appetite among officials for it. Journalists and advocates are more interested, but the agency seems to stick to its current plans even as their costs are setting non-New York construction cost records.

Is it at least good?

No. Somehow, for this cost, using a method whose primary advantage is that it makes it possible to build a station anywhere at the cost of massively more expensive tunneling, the station at the city’s main train station, named after still-alive Rod Diridon, will not be easily accessible from mainline rail. The walking distance is 400 meters, which has been justified on the grounds that “The decision had to do with impacts and entitlements. It’s also beneficial for the future intermodal station.”

It is, to be clear, not at all beneficial for a future intermodal BART-Caltrain station to require such a long walking distance, provided we take “beneficial” to mean “beneficial for passengers.” It may be beneficial for a Hollywood action sequence to depict characters running through such a space. It is not beneficial for the ordinary users of the station who might be interested in connecting between the two systems. There are 300 meter walks at some transfers in New York, and passengers do whatever they can to avoid them; I’ve taken three-seat rides with shorter transfers to avoid a two-seat ride with a long block transfer, and my behavior is typical of the subway users I know. Transfer corridors of such length are common in Shanghai and are disliked by the system’s users. It’s not the end of the world, but for $1.3 billion/km, I expect better and so should the people who have to pay for this project.

The United States Has Too Few Road Tunnels

The Francis Scott Key Bridge in Baltimore collapsed after a drifting freighter hit one of its supports; so far, six people are presumed dead. Immediately after the disaster, people were asking if it could be prevented, and it became clear that it is not possible to build a bridge anchor that can withstand the impact of a modern ship, even at low speed. However, it was then pointed out to me on Mastodon that it’s not normal in Europe to have such a bridge over a shipping channel; instead, roads go in tunnel. I started looking, and got to a place that connects my interest in construction costs with that of cross-cultural learning. Europe has far more road tunneling than the US does, thanks to the lower construction costs here; it also has better harmonization of regulations of what can go in tunnels and what cannot. The bridge collapse is a corner case of where the American system fails – it’s a once in several decades event – but it does showcase deep problems with building infrastructure.

Road tunnels

The United States has very little road tunneling for its size. This list has a lot of dead links and out of date numbers, but in the US, the FHWA has a current database in which the tunnels sum to 220 km. Germany had 150 km in 1999, and has tendered about 170 km of new tunnel since 2000 of which only 48 are still under construction. France has 238 km of road tunnel; the two longest and the 10th longest, totaling 28 km, cross the Alpine border with Italy, but even excluding those, 210 is almost as much as the US on one fifth the population. Italy of course has more tunneling, as can be expected from its topography, but France (ex-borders) and Germany are not more mountainous than the US, do not have fjords and skerries like Norway, and don’t even have rias like Chesapeake Bay and the Lower Hudson. Japan, with its mountainous island geography, has around 5,000 km of road tunnel.

The United States builds so few tunnels that it’s hard to create any large database of American road tunnels and their costs. Moreover, it has even fewer urban road tunnels, and the few it does have, like the Big Dig and more recently the Alaskan Way Viaduct replacement tunnel, have become bywords for extreme costs, creating distaste even among pro-highway urban politicians for more and leading to project cancellations. With that in mind, the State Route 99 tunnel replacing the Alaskan Way Viaduct is 3 km long and cost $2.15 billion in 2009-19, which is $2.77 billion in 2023 dollars and $920 million/km, with just four lanes, two in each direction.

In Europe, this is not at all an exhaustive database; it represents where I’ve lived and what I’ve studied, but these are all complex urban tunnels in dense environments:

- Stockholm: the six-lane Förbifart Stockholm project to build long bypass roads in Stockholm using congestion pricing money, after acrimonious political debates over how to allocate the money between roads and public transport, comprises 17 km of tunnel (plus 4 km above-ground) including underwater segments, for an updated cost of 51.5 billion kronor in 2021 prices, or $6.97 billion in 2023 PPPs, or $410 million/km. The project is well underway and its current cost represents a large overrun over the original estimate.

- Paris: the four-lane A86 ring road was completed in 2011 with 15.5 km of new tunnel, including 10 in a duplex tunnel, at a cost of 2.2 billion €. I’ve seen sources saying that the cost applies only to the duplex section, but the EIB claims 1.7 billion € for the duplex. Physical construction was done 2005-7; deflating from 2006 prices, this is $4.18 billion in 2023 PPPs, or $270 million/km. This is a tunnel with atypically restricted clearances – commercial vehicles are entirely banned, as are vehicles running on compressed natural gas, due to fire concerns after the Mont-Blanc Tunnel fire.

- Berlin: the four-lane 2.4 km long Tunnel Tiergarten Spreebogen (TTS) project was dug 2002-4, for 390 million €, or $790 million in 2023 PPPs and $330 million/km. This tunnel goes under the river and under the contemporarily built Berlin Hauptbahnhof urban renewal but also under a park. The controversial A100 17th segment plan comprises 4.1 km of which 2.7 are to be in tunnel, officially for 800 million € but that estimate is out of date and a rougher but more current estimate is 1 billion €. The exchange rate value of the euro today belies how much stronger it is in PPP terms: this is $1.45 billion, or $537 million/km if we assume the above-ground section is free, somewhat less if we cost it too. The 17th segment tunnel is, I believe, to have six lanes; the under-construction 16th segment has six lanes.

Crossing shipping channels

The busiest container ports in Europe are, by far, Rotterdam, Antwerp, and Hamburg, in this order. Rotterdam and Antwerp do not, as far as I’ve been able to tell from Google Earth tourism, have any road bridge over the shipping channels. Hamburg has one, the Köhlbrandbrücke (anchored on land, not water), on the way to one of the container berths, and some movable bridges like the Kattwykbrücke on the way to other berths – and there are plans to replace this with a new crossing, by bridge, with higher clearance below, with a tunnel elsewhere on the route. The next tranche of European ports are generally coastal – Le Havre, Bremerhaven, Valencia, Algeciras, Piraeus, Constanța – so it is not surprising the shipping channels are bridge-free; but Rotterdam, Antwerp, and Hamburg, are all on rivers, crossed by tunnel.

American ports usually have bridges over shipping channels, even when they are next to the ocean, as at the Ports of Los Angeles and Long Beach. This is not universal – crossings in Hampton Roads have tunnels – but it’s the trend. Of note, the US does occasionally tunnel under deep channels (again, Hampton Roads); that the Netherlands tunnels in Rotterdam is especially remarkable given how Holland is a floodplain with very difficult tunnel construction in alluvial soil.

Hazardous material regulations

Tunnels do not permit all traffic, due to fire risk. For example, the Mont-Blanc Tunnel requires vehicles heavier than 3.5 tons to undergo a safety inspection before entering to ensure they don’t carry prohibited dangerous goods. In Europe, this is governed by the ADR; all European countries are party to it, even ones not in the EU, and so are some non-European ones. Tunnels can be classified locally between A (no restrictions) and E (most restrictive).

The United States is not party to the ADR. It has its own set of regulations for transportation of hazardous materials (hazmat), with different classifications – and those differ by state. Here are the rules in Maryland. They’re restrictive enough that significant road freight had to use the Key Bridge, because the alternative routes have tunnels that it is banned from entering. Port Authority has different rules, permitting certain hazmat through the Lincoln Tunnel with an official escort. Somehow, the rules are not uniform in the United States even though it is a country and Europe is not; Russia and Ukraine may be at war with each other, but they have the same transportation of dangerous goods regulations.

Costs Per Rider and Willingness to Build

At the Transit Costs Project, we study the costs of urban rail lines per kilometer. This, with our usual controls, is a rough indicator of how efficient a city’s infrastructure construction program is. However, cost-effectiveness is different from efficiency, and is better measured not by just the cost but also the benefits, which are measured by ridership. Thus, cost-effectiveness is best measured by the cost of each project per rider. So what does it mean to compare different cities by their costs per rider, rather than per kilometer?

The answer is, “not much,” at least not as far as efficiency or good decisionmaking. In fact, while some projects persistently have costs per rider that are too high to be cost-effective (for example, it’s endemic to airport extensions), some cities have costs per rider that are too low, such as Berlin. The issue here is that if municipal or state decisionmaking is healthy, it will build cost-effective lines; if a line under discussion has a very high benefit-cost ratio, or equivalently a very low cost per rider, it means it should have been built long ago, and it speaks poorly to the local decisionmaking that it hasn’t been built already, as is unfortunately the case in Berlin.

Cost per rider and cost-effectiveness

As always, let’s start with Second Avenue Subway Phase 1, the project that launched my interest in construction costs and the Transit Costs Project writ large. The projected daily ridership is 202,000; the line came close to it in 2019, reaching about 163,000 (see data here; I’m taking boardings for the three new stations, adding the growth in ridership at Lexington/63rd, and multiplying by two to account for disembarkings), and would have likely reached projection by now but for the pandemic. The cost, in 2023 dollars, was $6.23 billion, or about $31,000 per projected weekday trip.

For another anchoring number, let’s use the Stockholm Metro’s entire construction from the 1940s to the 1970s. This is useful because in addition to costs per rider, there is a published ex post benefit-cost ratio, thanks to the work of Maria Börjesson. The cost of that system, in 2023 PPP dollars, was $3.7 billion, with a ridership of 1,265,900 per workday in 2019, or $2,900/rider, while the benefit-cost ratio is 6 without taking agglomeration into account, or 8.5 with. This does not mean that the value of a rider is only about $24,900; this was the value in the economic situation of postwar Sweden, a country that was substantially poorer than the Sweden of today. In 2023 PPP terms, Sweden’s GDP per capita in 1965, about midway through the opening of the original system, was about $19,400; today, Sweden is 3.5 times richer, and the US is 17% richer than Sweden.

The benefits of urban travel are largely proportional to GDP per capita. The economic benefits of agglomeration are proportional to the value of the economy writ large, and so are the benefits of reduced travel time, which in benefit-cost analyses are usually taken to be proportional to the average hourly wage. Conversely, the ability of a government to spend money on desired outcomes is proportional to its tax base, i.e. the size of its economy. All of this is approximate, but all we’re doing is first-order approximate analysis anyway, and so correcting for GDP per capita is valuable.

As it is, the difference between American and Swedish GDP per capita boils down entirely to working hours. Swedes work shorter hours than Americans, as they, like nearly everyone else in Europe, get much longer vacation time; as of 2022, Sweden’s GDP per hour worked was, by a rounding error, slightly higher than the US’s. However, at the same time, the daily ridership numbers for Sweden are specifically drawn from winter workday ridership, to avoid reporting figures from when ridership is lower during the summer vacation season, and the same is true for daily ridership counts in France. If we give Sweden and France credit by looking at ridership when people aren’t on vacation, we must compare the cost per rider with GDP per capita and not GDP per hour.

The upshot is that countries should be building metros up to a maximum capital cost per rider that’s about as large as their GDP per capita. The $24,900 computation for 1960s’ Sweden is ex post, and usually the ex ante benefit-cost ratio must be at least 1.2 or 1.3 for the project to go ahead due to risk. For light rail the allowable cost should be lower, and for bus projects it should be lower still, due to the higher lifetime operating costs; but for metros and metro-like urban rail projects (such as largely grade-separated light rail, or commuter rail tunnels like Citybanan), this analysis should hold. Second Avenue Subway Phase 1, which opened in a United States with a GDP of $73,300/capita in 2023 prices, is thus very cost-effective; Phase 2, budgeted at something like $70,000/rider in today’s prices, is marginal but makes it (in 2022, US GDP per capita in 2023 prices was $80,300).

Some more costs per rider

Our database of construction costs per km is largely complete, but we don’t have much ridership data. Worse, the costs per rider we do have have some biases. We have better information for the US and Canada than elsewhere, and for Europe than the rest of the non-North American world. Costs are also likeliest to be reported for megaprojects with notable delays or cost overruns and thus an incomplete database will be biased upward; large, international cities have better reporting in English than the rest and this introduces another upward bias in incomplete data (these are typically wealthy and therefore capable of affording a high cost per rider).

With that in mind, here are some (again, incomplete) examples:

- Crossrail cost $24 billion in 2023 PPP terms; ridership in late 2023 was 4.3 million a week, which is usually about 700,000/weekday, said to be above projections, with long-term projections rising to a million/weekday; on current ridership it’s $34,000/rider, and on future projections it’s $24,000.

- Paris Métro Line 14’s original section, opened by 2007, cost $2.44 billion in 2023 PPP terms; ridership in 2019, before more recent extensions and before corona, was 92 million, so around 320,000 per workday, which is $7,600/rider.

- Grand Paris Express was projected in 2021 to cost (in 2023 PPP dollars) around $65 billion, with a ridership projection of 2 million/day from 2022, and 2.3-2.4 million/day from 2012, for around $32,000/rider, or $28,000 if the older ridership projection is used.

- Milan Metro Line 5 cost $2.2 billion in 2023 PPP terms to date, and was said to carry 180,000 daily passengers in 2019, for $12,000/rider.

- Milan Metro Line 4 cost $2.63 billion, and was expected to carry 235,000 riders per day when complete, which would be $11,000/rider; it will be completed this year, but ridership so far is for only the half of the line that has opened so far ans is also still somewhat suffering from corona.

- The U-Bahn extensions in Berlin that are currently in development hell include U8 to Märkisches Viertel projected at 13,160€/rider (around $21,000 in 2023 PPP terms), a U6 extension to the former Tegel Airport projected at 27,200€/rider (around $43,000), and a U7 extension to the current BER airport projected at 23,000€/rider (around $36,000), among others brought up by the new coalition.

Willingness to build and Berlin’s problem

The above numbers should not be taken to mean that Italy and Germany are more cost-effective about metro construction. To the contrary, they indicate that they are leaving value on the table by not building.

Germany has a GDP per capita of $66,000 in PPP terms. The benefit-cost ratios of the U-Bahn extensions in Berlin that are being discussed but not actually brought forward and built are very high, and the U8 extension to Märkisches Viertel is scratching a ratio of 4. It is irresponsible that there isn’t a massive construction plan not just under discussion but in design and soon physical construction. This must include not just those lines but also others to be added until the benefit-cost ratio of the marginal line falls to slightly more than the minimum that deserves funding.

Italy has the same problem. No matter how pessimistic one’s view of the future of the economy of Italy is, the metro lines it is currently building, at least in Milan, are so cost-effective that there have to be more of them. In the 2010s, Italy was in a budget crunch and ended up using public-private partnerships to keep debt off-books, at very high implied interest rate based on the rate of payment to the concessionaire, about 8%. Today, fundamentally, even a stagnant economy with a GDP per capita of $55,000, which may finally overtake its 2007 peak this year, should be building more if the current extensive margin of Milan Metro construction is not even in the teens of thousands of dollars. Perhaps the benefit-cost ratios for Sweden rely not just on Sweden’s GDP per capita of the 1960s but on that of today, after 60 years of growth; but then even absent any of this growth, 55/3.5 > 12.

Paris showcases a healthier situation: the success of M14 endeared the region to driverless metros with longer interstations than the older metro lines but shorter ones than the RER, and with further growth in the region, the state decided to build the 200 km Grand Paris Express to improve circumferential rail service and add more fast radial connections from the suburbs to the city not along the RER. France’s GDP per capita is around $58,000 in PPP dollars; some elements of GPE may be marginal, but the project writ large has a solid benefit-cost-ratio starting with a 2.

Spain is like France in that when it can build, as it could before the Great Recession and as it can now after having recovered, it does. This is the right way to do it: low costs per km should translate to massive subway expansion. If you’re Madrid, you can build lines that would be completely ridiculous anywhere else in terms of land use, like MetroSur, because it’s cheap.

A Paris or Berlin cannot be so profligate as Madrid. Building a line like MetroSur here, which in the Spanish context looks silly but does pass cost-effectiveness muster, would be an economic albatross. But medium-cost cities can still cover most of the built-up area with subway and commuter rail lines; Paris is doing so but Berlin is not.

The problem for Berlin is not quite austerity, which afflicted Southern Europe last decade, producing negative economic growth. In the last coalition, it was the two most left-wing parties, the Greens and Die Linke, which opposed U-Bahn construction. In their view, trams are preferable; they complain about the high construction costs of subways, but don’t meaningfully engage with why they’re still necessary for fast urban transport beyond the range of the handful of inner neighborhoods where people vote for the Greens.

That said, in the current coalition, there’s no real political left. SPD is in it, but under an atypically conservative leader in Franziska Giffey, and the more left-wing faction in the party, including the youth league Jusos, is sidelined. Both parties in the coalition, CDU and SPD, are committed to building those U-Bahn extensions. But then nothing is happening; Giffey is not competent enough to do it, and CDU is too wrapped up in anti-environmental populism to do something that pisses off some environmentalists but makes others happy.

This way, the low costs per rider projected for Berlin U-Bahn expansion are not a testimony to cost-effectiveness. They’re a testimony to political unwillingness to build, for largely petty reasons. It is wasteful to build a subway line with a very high projected cost per rider relative to the country’s wealth, but it is equally wasteful not to build one with a low projected cost per rider, and the latter is what is happening in Berlin, unfortunately.

Cost-Plus Contracting is Good

Because I write a lot about government waste, I get to interact with people who complain a lot about government waste, which exposes me to a range of views, some more reasonable than others. The less reasonable views themselves range from unhinged rants to things that sound like they could be true, that may even be true for parts of contracting other than public transportation or infrastructure megaprojects. It’s one of the latter views that I wish to talk about here. It’s all too common, in my experience, for people who complain about government waste in the United States to speak ill of cost-plus contracting, which they claim (incorrectly but plausibly) is a form of a waste and even (much less plausibly) fraud, in which contractors get paid regardless of how poor the job is. In truth, the only good way to build infrastructure megaprojects is with itemized contracts and with generous public-sector assumption of risk; this isn’t called cost-plus in the literature but itemization, but is close enough that from the perspective of citizen-activists it should be viewed as a cost-plus variant.

Itemization versus fixed-price contracting

Contracts can, broadly, be either itemized or fixed-price, the latter also known as lump-sum. A fixed-price contract has a single cost line for the entire project; an itemized contract instead prices each section, and certain elements that are agreed to be outside the contractor’s control, like materials, are adjusted automatically if prices on the world market change.

There are also mixed models. For example, in Stockholm, some contracts are fixed-price, some itemized, and others use an intermediate system called fixed price with adjustable quantities, in which some elements are itemized but others are not. Turkish construction contracts itemize about 65% of the costs in detail, covering the civil infrastructure, and then take each of the main sub-items of the other 35% (at the detail level of ventilation, power design, sewage, etc.) as a fixed-price contract.

In Southern Europe and Turkey, the items are public, published transparently by the government, as an anti-corruption measure. These are detailed, and take different costs of living into account, and thus in Italy the prices, published by the state, may differ by region. If the itemized prices are unrealistic, then the contractors are allowed to demand more, but those itemized lists help ground the contract.

This system far outperforms fixed-price contracts. We have standard references on this, namely Ryan (1, 2) and Bolotnyy-Vasserman, finding that itemization for power plants (in Ryan) or road maintenance (in Bolotnyy-Vasserman) leads to reduced overall costs, by about 20%. The reasons are that fixed-price contracting leads to increased friction in change orders, and that, relatedly, fixed-price contracting imposes risk on the private contractor, leading to higher bids for compensation. For this reason, all low-construction cost environments we’ve investigated itemize, to a significant extent. The Nordic countries are moving from itemized to fixed-price contracting under the influence of British practices and the requests of large international firms that are used to doing business in English-speaking countries or in other high-cost countries, and as they do so, their costs are moving from low to medium, in addition to other bad reforms.

So why do people think itemization is bad?

The big multinationals are just used to fixed-price contracts. In New York (where it’s usually not big multinationals), an additional issue is that the contractors prefer to be paid upfront, due to delays in payment under itemization. But more commonly, the contractors just don’t like having to give exact specifications, and are used to environments where they don’t and don’t notice how the costs in those places are much higher than in places that don’t govern in English.

But government contractors are hardly a popular figure among people who complain about government waste. So what gives?

I suspect that this is about the sight of the government assuming risk for something a private contractor does. The sight of a contractor complaining about a problem that the government then has to pay extra for is repulsive to the general public, which assumes that something shady is going on, regardless of whether it is. This leads to political pressure to insulate the public sector from unexpected changes.

The problem is that there is no way to fully insulate the public sector. Once the megaproject has been decided, the political cost for the government of walking away is larger than the economic penalties for the concessionaire. In practice, every attempt to privatize risk will get contractors to bid higher, while still not protecting the public from the risk of large cost overruns. Turkey is somewhat exceptional in this, but it still itemizes, and the way it enforces the maximum 20% cost overrun is by having so many contractors that it’s easy to blacklist malefactors; this is not available in richer countries with fewer, larger firms.

Janno Lieber Lies to New York About Costs and Regulations

After being criticized about the excessive size of subway stations designed on his watch, MTA head Janno Lieber fired back defending the agency’s costs. In a conversation with the Manhattan Institute, he said about us, “They’re not wrong that the stations are where the MTA stations add cost. But they are wrong about how they compare us – the cost per mile is misleading” (see discussion on social media here). Then he blamed labor and the fire code. Blaming labor is a small but real part of the story; this is common among the white-collar managers Eric and I have talked to, and deserves a separate explanation for why this concern is overblown. But the issue of the fire code is fraud, all the way.

I’ve previously seen some journalists and advocates who write about American construction costs talk about fire safety, which is mentioned occasionally as a reason designs cannot be changed. It’s not at all what’s going on, for two separate reasons, each of which, alone, should be grounds to dismiss Lieber and ensure he never works for the state again.

The first reason is that the fire safety regulation in the United States for train stations, NFPA 130, has been exported to a number of other countries, none of which has American costs or the specific American tradition of overbuilding stations. China uses NFPA 130. So does Turkey. Spain uses a modification. We can look at their designs and see that they do not build oversize stations. I’ve seen an environmental impact analysis in Shanghai, with the help of a Chinese student studying this issue who explained the main planning concerns there. I could write an entire blog post about China (not a 10,000-word case report, of course), but suffice is to say, if the train is projected to be 160 m long, the station dig will be that plus a few meters – and Chinese stations have mezzanines as I understand it. Spanish and Turkish stations have little overage as well; building a dig twice as long as the station’s platforms to house back-of-the-house spaces is unique to most (not all) of the Anglosphere, as design consultants copy bad ideas from one another.

Even the claim that NFPA 130 requires full-length mezzanines is suspect. It requires stations to be built so that passengers can evacuate in four minutes in emergency conditions, rising to six minutes counting stragglers (technically, the throughput needs to be enough to evacuate in four minutes, but with latency it can go up to six). The four minute requirement can be satisfied on the lettered lines of the subway in New York with no mezzanines and just an access point at each end of the platform, but it’s close and there’s a case for another access point in the middle; no full-length mezzanine is required either way. If the stations are any shorter, as on the numbered lines or in other North American cities, two escalators and a wide staircase at the end of each platform are more than enough, and yet the extensive overage is common in those smaller systems too (for example, in Vancouver, the Broadway extension is planned with 128 m long digs for 75 m trains, per p. 9 here).

“Fire safety” is used as an excuse by people with neither engineering background nor respect for anything quantitative or technical. Lieber is such a person: his background is in law and he seems incurious about technical issues (and this is also true of his successor at MTA Capital Construction, public policy grad Jamie Torres-Springer).

Perhaps due to this lazy incuriosity, Lieber didn’t notice that the MTA has extensive influence on the text of NFPA 130, bringing us to the second reason his claim is fraudulent. NFPA 130 is not to blame – again, it’s the same code as in a number of low- and medium-cost countries – but Nilo Cobau explains that the NFPA process is such that big agencies have considerable input, since there aren’t many places in the US that build subways. Nolan Hicks pointed out in the same thread, all linked in the lede paragraph, that the MTA has a voting member and two alternates on the board that determines NFPA 130 and hasn’t requested changes – and that Montreal, subject to the same codes, built a station with little overage (he says 160 m digs for 150 m platforms).

The handwaving of a fire code that isn’t even different from that of cheaper places is there for one purpose only: to deflect blame. It was a struggle to get Lieber and other New York leaders to even admit they have high costs, so now they try to make it the fault of anyone but themselves: fire safety regulations, organized labor, what have you.

Labor is a real issue, unlike fire safety, but it’s overblown by managers who look down on line workers and have generally never been line workers. Lieber graduated law school, was hired by USDOT at either junior-appointed or mid-level civil servant role, I can’t tell which, and then did managerial jobs; his successor as head of MTA Construction and Development, Jamie Torres-Springer, graduated public policy. These aren’t people who worked themselves up from doing engineering, architecture, planning, or ethnographic work; add the general hostility American white-collar workers have toward blue-collar workers, and soon people in that milieu come to believe that just because their top 5%er wages are much higher than they could earn anywhere else in the world, the sandhogs also earn much more than they could anywhere else in the world, when in truth New York sandhog and Stockholm miner wages and benefits are very close.

Occasionally the point that it’s not wages but labor productivity seeps in. There, at last, we see a real problem with labor. Eric and I found that about a third of the sandhogs on Second Avenue Subway didn’t really need to be there. Further cuts could be achieved through the use of more labor-efficient techniques, which the MTA is uninterested in implementing. The rest of the American labor premium comes from excessive staffing of white-collar supervisors, including representatives from each utility, which insists that the MTA pay for the privilege of having such representatives tell them what they can and cannot do in lieu of mapping the utilities and sending over the blueprints. All included, labor was around 50% of the cost of Second Avenue Subway, where the norm in Italy, Turkey, and Sweden is around 25% (note how higher-wage Sweden is the same as lower-wage Italy and much lower-wage Turkey); excessive labor costs contributed a factor of 1.5 premium to the project, but the other factor of 6 came from excessive station size, deep mining of stations (which thankfully will not happen at 106th and 116th Street; it will at 125th but that’s unavoidable), lack of system standardization, and a litany of project delivery problems that are generally getting worse with every iteration. Lieber personally takes credit for some of the privatization of planning to design-build consultancies, though to be fair to him, the project delivery problems predate him, he just made things slightly worse.

A New York that wants to build will not have incompetent political appointees in charge. It will instead hire professionals with a track record of success; as no such people exist within the American infrastructure construction milieu, it should use its own size and prestige to find someone from a low-cost city to hire, who will speak English with an accent and know more engineering than American legal hermeneutics. And it will not reward people who defraud the public about the state of regulations just because they’re too lazy to know better.

The MTA Sticks to Its Oversize Stations

In our construction costs report, we highlighted the vast size of the station digs for Second Avenue Subway Phase 1 as one of the primary reasons for the project’s extreme costs. The project’s three new stations cost about three times as much as they should have, even keeping all other issues equal: 96th Street’s dig is about three times as long as necessary based on the trains’ length, and 72nd and 86th Street’s are about twice as long but the stations were mined rather than built cut-and-cover, raising their costs to match that of 96th each. In most comparable cases we’ve found, including Paris, Istanbul, Rome, Stockholm, and (to some extent) Berlin, station digs are barely longer than the minimum necessary for the train platform.

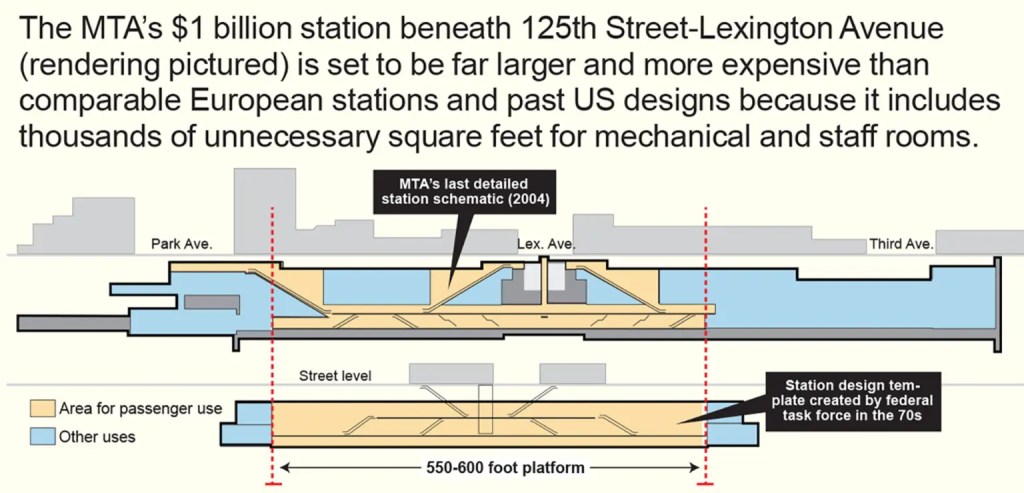

MTA Construction and Development has chosen to keep building oversize stations for Second Avenue Subway Phase 2, a project that despite being for the most part easier than the already-open Phase 1, is projected to cost slightly more per kilometer. Nolan Hicks at the New York Post just published a profile diagram:

The enormous size of 125th Street Station is not going to be a grand civic space. As the diagram indicates, the length of the dig past the platforms will not be accessible to passengers. Instead, it will be used for staff and mechanical rooms. Each department wants its own dedicated space, and at no point has MTA leadership told them no.

Worse, this is the station that has to be mined, since it goes under the Lexington Avenue Line. A high-cost construction technique here is unavoidable, which means that the value of avoiding extra costs is higher than at a shallow cut-and-cover dig like those of 106th and 116th Streets. Hence, the $1 billion hard cost of a single station. This is an understandable cost for a commuter rail station mined under a city center, with four tracks and long trains; on a subway, even one with trains the length of those of the New York City Subway, it is not excusable.

When we researched the case report on Phase 1, one of the things we were told is that the reason for the large size of the stations is that within the MTA, New York City Transit is the prestige agency and gets to call the shots; Capital Construction, now Construction and Development, is smaller and lacks the power to tell NYCT no, and from NYCT’s perspective, giving each department its own break rooms is free money from outside. One of the potential solutions we considered was changing the organizational chart of the agency so that C&D would be grouped with general public works and infrastructure agencies and not with NYCT.

But now the head of the MTA is Janno Lieber, who came from C&D. He knows about our report. So does C&D head Jamie Torres-Springer. When one of Torres-Springer’s staffers said a year ago that of course Second Avenue Subway needs more circulation space than Citybanan in Stockholm, since it has higher ridership (in fact, in 2019 the ridership at each of the two Citybana stations, e.g. pp. 39 and 41, was higher than at each of the three Second Avenue Subway stations), the Stockholm reference wasn’t random. They no longer make that false claim. But they stick to the conclusion that is based on this and similar false claims – namely, that it’s normal to build underground urban rail stations with digs that are twice as long as the platform.

When I call for removing Lieber and Torres-Springer from their positions, publicly, and without a soft landing, this is what I mean. They waste money, and so far, they’ve been rewarded: Phase 2 has received a Full Funding Grant Agreement (FFGA) from the United States Department of Transportation, giving federal imprimatur to the transparently overly expensive design. When they retire, their successors will get to see that incompetence and multi-billion dollar waste is rewarded, and will aim to imitate that. If, in contrast, the governor does the right thing and replaces Lieber and Torres-Springer with people who are not incurious hacks – people who don’t come from the usual milieu of political appointments in the United States but have a track record of success (which, in construction, means not hiring someone from an English-speaking country) – then the message will be the exact opposite: do a good job or else.

Boston Meetup and Consultants Supervising Consultants

The meetup was a lot less formal than expected; people who showed up included loyal blog readers (thank you for reading and showing up!), social media followers (same), and some people involved in politics or the industry. I don’t have any presentation to show – I talked a bit about the TransitMatters Regional Rail program and then people asked questions. Rather, I want to talk about something I’ve said on social media but not here, which I delivered a long rant about to the last people who stayed there.

The issue at hand is that the only way that seems to work to deliver complex infrastructure projects is with close in-house supervision. This is true even in places where the public-sector supervisors, frankly, suck – which they frequently do in the United States. It’s fine to outsource some capabilities to consultants, but if it happens, then the supervision must remain in the public sector, which requires hiring more in-house people, at competitive salaries.

Why?

The reason is that public-sector projects always involve some public-sector elements. This is true even in the emergent norm in the English-speaking world and in many other countries that take cues from it, in which not only is most work done by consultants, but also the consultants are usually supervised by other consultants. The remains of the public sector think they’re committed to light-touch supervision, but because they, by their own admission, don’t know how to do things themselves or even how to supervise consultants, they do a bad job at it.

The most dreaded request is “study everything.” It’s so easy to just add more scenarios, more possibilities, more caveats. It’s the bane of collaborative documents (ask me how I know). In the Northeast Corridor timetabling project I’m doing with Devin Wilkins, I could study everything and look at every possible scenario, with respect to electrification, which projects are undertaken, rolling stock performance profile, and so on. It would not be doable with just me and her in a year or so; I would need to hire a larger team and take several years, and probably break it down so that one person just does Boston, another just does Philadelphia, a third just does Washington and Baltimore, several do New York (by far the hardest case), and one (or more) assists me in stapling everything together. The result might be better than what we’re doing now, thanks to the greater detail; or it might be worse, due to slight inconsistencies between different people’s workflows, in which case a dedicated office manager would be needed to sort this out, at additional expense. But at least I’d study everything.

Because I’m doing this project for Marron and not for an American public-sector client, I can prune the search tree, and do it at relatively reasonable expense. That’s partly because I’m the lead, but also partly because I know what I’m doing, to an extent, and am not going to tell anyone “study everything” and then dismiss most scenarios after three months of no contact.

The behavior I’m contrasting myself with is, unfortunately, rife in the American public sector. And it’s the most common among exactly the set of very senior bureaucrats, often (not always) ones who are there by virtue of political appointment rather than the civil service process, who swear that consultants do things better than the public sector. There’s no real supervision, and no real narrowing of the process. This looks like an alternative to micromanagement, but is not, because the client at the end does say “no, not like this”; there’s a reason the consultants always feel the need to study everything rather than picking just a few alternatives and hoping the client trusts them to do it right.

It’s telling that the consultants and contractors we speak to don’t really seem happy with how they’re treated by the public-sector client in those situations. They’re happy when interfacing with other private actors, usually. I imagine that if I hired a larger team (which we don’t have the budget for) and gave each person a separate task, they’d be really happy to have come up with all those different scenarios for how to run trains in the Baltimore-Washington area, interfacing with other equally dedicated people doing other tasks of this size. When consultants are supervised by other consultants, only the top-level consultant interfaces with the remains of the civil service, hollowed out by hiring freezes, uncompetitive salaries, and political scourging; the others don’t and think things work really smoothly. This, I think, is why opaque design-build setups are so popular with the private consultants who are involved in them: by the time a country or region fully privatizes its supervision to a design-build consultant, its public sector has been hollowed so much that the consultants prefer to be supervised privately, even if the results are worse.

In contrast, the only way forward is a bigger civil service. This means hiring more people, in-house, and paying them on a par with what they would be earning in the private sector given their experience. As I said at the bar a few hours ago, I’m imagining someone whose CV is four years at the MTA, then five at a consultant, then four at the MBTA, and then six at a consultant; with these 19 years of experience, they could get hired at a senior engineer or project manager position, for which the market rate in Boston as I understand is in the high $100,000s. For some things, like commuter rail electrification, there are unlikely to be any suitable candidates from within the US, and so agencies would have to hire a European or Asian engineer.

With competitive salaries, people would move between different employers in the same industry, as is normal in American and European industries. They could move between public and private employers, because the wages and benefits should be similar. They’d pick up experience. An agency like the MBTA, with its five to six in-house design review engineers, could staff up appropriately to be able to supervise not just small projects like infill commuter rail station, which it built at reasonable cost on the Fairmount Line, but also large ones like the Green Line Extension and South Coast Rail, which it builds at outrageously high costs.